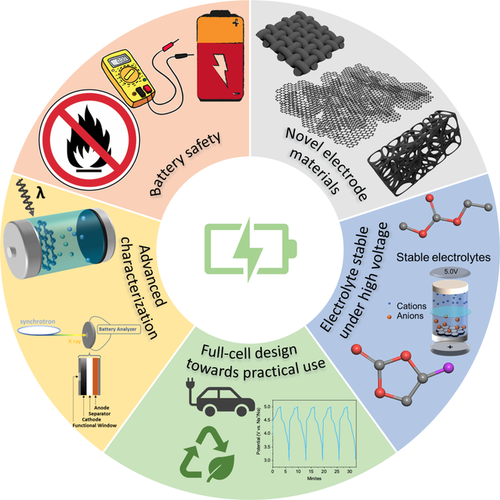

Collabrating with University College London Electrochemical Innovation Lab (UCLEIL), we have produced a cheaper, more sustainable and energy-dense electrode material for supercapacitors which could pave the way for wider market penetration of this high-power, quick charging electric vehicle technology.

doi.org/10.1002/advs.202100016

https://www.imperial.ac.uk/news/223353/new-generation-supercapacitors-electrify-green-transportation/

Supercapacitors are increasingly used in short-distance electric transportation due to their long lifetime (≈15 years) and fast charging capability (>10 A g−1). To improve their market penetration, while minimizing onboard weight and maximizing space-efficiency, materials costs must be reduced (<10 $ kg−1) and the volumetric energy-density increased (>8 Wh L−1). Carbon nanofibers display good gravimetric capacitance, yet their marketability is hindered by their low density (0.05–0.1 g cm−3). Here, the authors increase the packing density of low-cost, free-standing carbon nanofiber mats (from 0.1 to 0.6 g cm−3) through uniaxial compression. X-ray computed tomography reveals that densification occurs by reducing the inter-fiber pore size (from 1–5 µm to 0.2–0.5 µm), which are not involved in double-layer capacitance. The improved packing density is directly proportional to the volumetric performances of the device, which reaches a volumetric capacitance of 130 F cm−3 and energy density of 6 Wh L−1 at 0.1 A g−1 using a loading of 3 mg cm−2. The results outperform most commercial and lab-scale porous carbons synthesized from bioresources (50–100 F cm−3, 1–3 Wh L−1 using 10 mg cm−2) and contribute to the scalable design of sustainable electrodes with minimal ‘dead volume’ for efficient supercapacitors.